Hello fellow growers. I thought to stir up this topic. Since 98’ when i first started to grow 2 YPS in a 4×4👣was the standard. With all the advances in every area of the industry the standard hasn’t increased. Today it is known as 2.5 YPS is with a 5×5👣. I just recently read 3. That did not surprise me.

I thought to share, and hear some extraordinary grow stories regarding yield.

It is imperative that we only talk about Sativa Dominant Indoor Grow yields…

As it is my hope that the standard double to 5YPS

There you go @420falcon . Lovely topic. Lets get it amped up and welcome to GN.

Thank you once again

I’m guessing PPPL = Pound Per Plant?

@Homey , going to share @420falcon initial message to me for more detail:

The New Standard

Based on INDOOR Exotic Yield.

PPPL (Pounds Produced Per Light)

5’x5’ Footprint

The Current Standard is ?

My understanding is since i started its 2PPPL. Over the years 2.25-2.5 has been mentioned, for a lack of a better word.

Just recently i read 3, for the first time and that did not surprise me. I know nothing else.

I just read a few minutes ago based on square footage of 35 million, 5 million pounds were produced? Was it indoor or outdoor? That equates to 7PPPL if it were all indoor and 5x5 for which only theoretical physics could prove.My experiences with a 4’x4’ Footprint

I started in 98’. My first time 1PPPL

In 99’ once, 4PPPL, 80 pounds/21 lights

ok, not exactly 4. I was dubbed MaGwire, & like him, never did it again. Consistently/inconsistently

1.75-2.5 PPPL.

2005, Once 3.5 PPPL

Last year in Michigan 19ps 4 lights. I started to figure it out. Done in a crappy environment with antiquated equipment.Off to Oklahoma. I can assert with utter confidence in setting The New Standard!

Ever heard the adage, Talk the Talk?

That’s why I’m here… I will Double the current standard, arguably being 2.5.

I assert unequivocally, that I will yield 5PPPL of Indoor Exotic Strains in a 5’×5’ footprint.

Yield is the holy grail of cannabis cultivation. So, it’s not surprising that most professional cultivators measure yield in some form. Most — nearly three-fourths (72%) of the cultivators who participated in CBT’s research project — say they measure yield per square foot. However, 38% of those who say they measure this metric didn’t know the actual yield per square foot of their cultivation operation’s most recent harvest, and some respondents who elaborated further on the question indicated they measure this metric somewhat informally.

Joe Romano of The Indoor Garden Shop in Detroit, Mich., who participated in the research project, says that his operation measures yield per square foot “in a roundabout way.” His team looks at “given a particular space, how many harvests can we get in a year,” he says.

Measuring yield per square foot, he believes, is one of the more important stats to track, if even informally, but looking at yield per strain also is important. “I think we spend more time balancing looking at different strains [and] … what they produce,” Romano says. “For example, the majority of what we’ve been growing lately is Gorilla Glue, [for] which yield per square foot is fantastic compared to a number of sativas. Ours have been more of a focus on a variety of plants and [their] marketability than anything else.”

Vince Hanson, cultivation director at Leaf on the Mesa in Pueblo, N.M., another participant in the research, also believes measuring yield per square foot is important (“You can have all these lights in the room, and you can be wasting a tremendous amount of square footage,” he says), but time constraints have not yet enabled his team to do so. “This grow started about a year and a half ago. We just got over all of our weird growing pains,” he says. “And so … the last six months, we’ve been producing steady.”

In the future, he says, Leaf on the Mesa will probably track this metric.

Right now, Hanson says, ‘We look more for our averages. … We have to do a wet plant weight and a dry plant weight, so when I enter everything into the metrics, I can find an average plant weight. So if I find a drop-off in the average plant weight, there’s something going on, wherever they came out of, or something going on with the strain. So I pretty much focus on average yield,” he adds. “I keep logbooks of everything. … I build spreadsheets for all of these and print them off. As they harvest plants, I write down its tag, its wet weight, its waste weight, its bud weight, all those things.”

Research participant Robert Mead of Sound Cannabis in Aberdeen, Wash., says his business does not measure yield per square foot, but, he says, “that’s something we’re going to be looking at specifically. I’m watching the market, and the prices are starting to come down. I see a lot of really cheap concentrates in the market, so I really want to look at my return on investment.”

Yield per square foot ranged among research participants from 60g/sq. ft. or more to less than 20g/sq. ft., but the average yield per square foot, during the most recent harvests, rested just about in the middle at 39.5g.

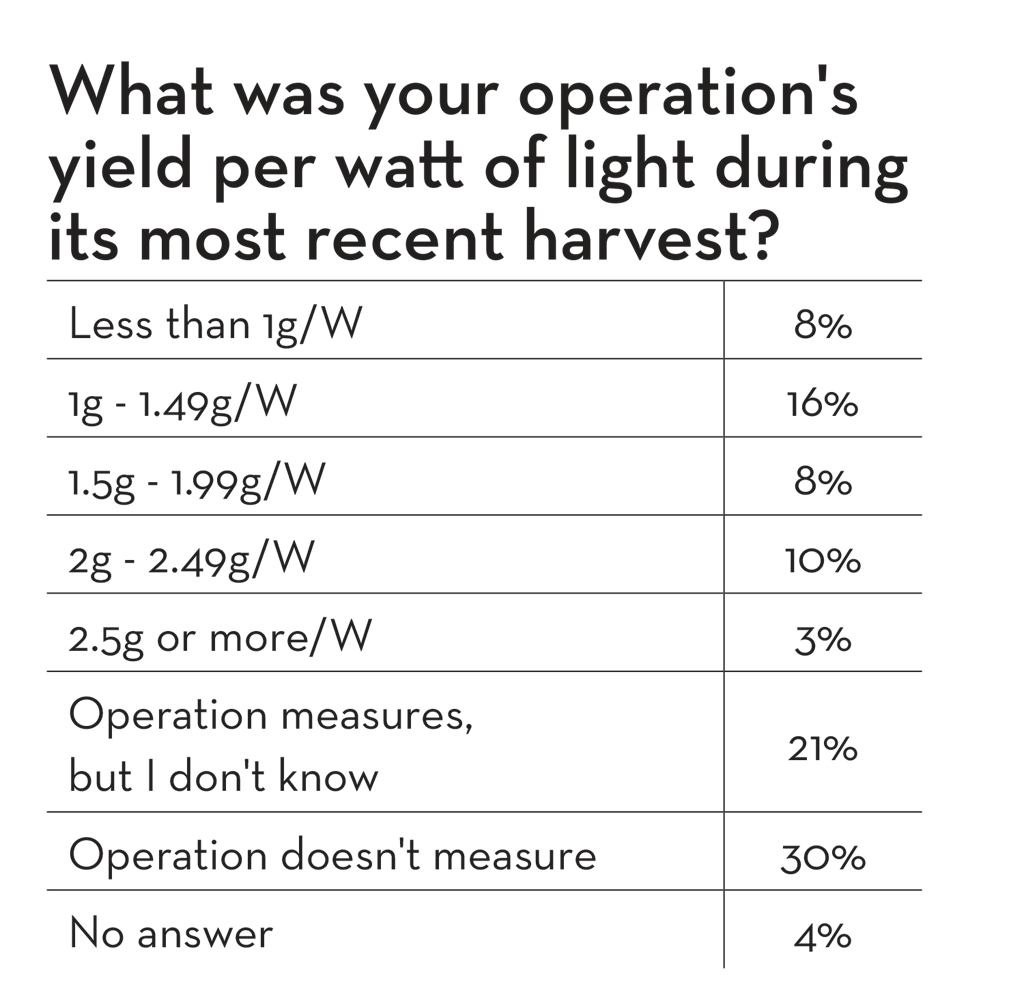

Another metric that some cultivators feel is even more important to measure than yield per square foot is yield per watt of light; however fewer measure this than yield per square foot. Two-thirds of respondents (66%) say they measure yield per watt of light; but, again, nearly one third (31%) of those cultivators say that their operations measures this, but that they don’t know what the yield per watt of light was during their most recent harvest.

Thirty percent of cultivators say they don’t measure yield per watt of light at all.

I think the Standard should be square footage. In that of itself you could figure out your costs and expenses to the penny.

For example they noted 2.5g per watt 3% of the time? That’s 5+YPS… That’s a bold statement…

at 2grw=2000 grams= 4.5 YPS

1.5 grw = 3.3 YPS

1 grw. = 2.2 YPS

And, was it GG#4?

Ok, Personally, I have to say that measuring yield per watt is far more useful than per light because lights vary in power and that’s not taken into account in that formula. Per watt is almost the same thing but it’s defined far more accurately. This is a great measurement to take to compare lights against each other as long as other factors are taken into account, distance from canopy, other environmental factors…

Yield per sqft is also a good measurement to use. And you don’t have to do a lot of calculating to get the answer. Divide the weight of your entire harvest of that room/tent/outside area by it’s sqft and there you go.

Both measurements are good to keep track of if you are any level of commercial grow as you can learn what’s wrong in the system by checking them combined with a few other measurements.

I see your point. In the car biz we had different guides to value cars.

That’s like saying this car has a bigger engine so you will get fewer speeding tickets because the cops can’t catch you. LOL

Dam… I like your metaphor better😜

If a 1000 Watt LED draws 800 Watt how would you calculate that?

I would use both actually, the lights rated power (1kw) versus actual power (800w) and then divide the total weight by each. This is another good indicator of light quality.

for example; Is this light really giving me 1000 watts of plants, or is it short? With the above example (1k/800) this light would be 20% short of it’s claims. 20% is serious. If you grow 10 plants but you only get to keep 8.

Harvested per SqFt = total harvest wet weight divided by total square feet of the area.

Dry harvest per sqft = Dry weight/sqft

Dry harvest per watt = Dry weight/total watts of light in area.

Wet harvest per watt = Pre dry harvest weight/total watts

Estimated Harvest based on light ratings = rated watts x average dry/wet harvest weight

This will tell you what the light should produce if it is really putting out that much power.

Excellent, thank you.

Did you by chance see the Planet 13 Video?

I’d very much like to know what their yielding for that’s gotta be as close to perfection as possible as far as an indoor grow operation? Am i wrong?

Sorry, I have not seen that video. I’ve been busy today.

I’ll have to check it out.