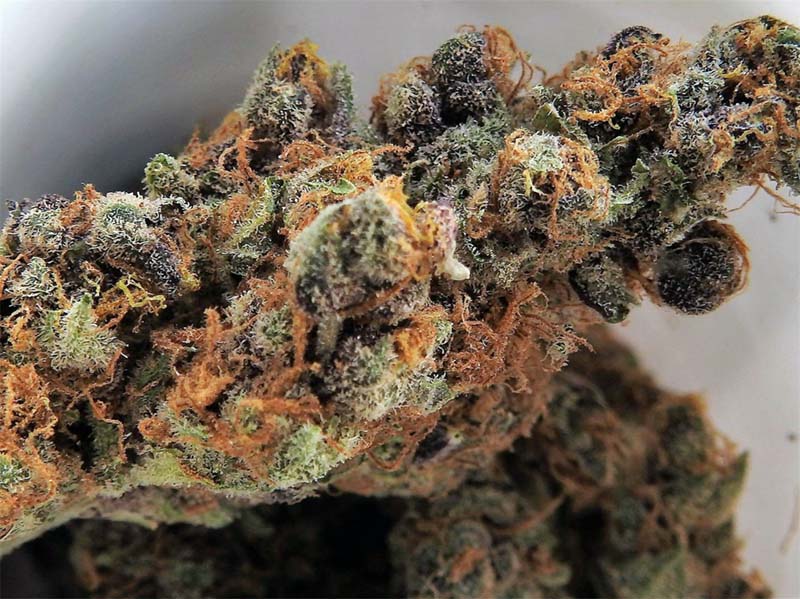

What constitutes ‘top-shelf cannabis’ is widely subjective, with different standards in disparate markets. In regulated markets the overwhelming majority of exceptional flower is grown indoors, where master cultivators can employ their knowledge, skills and passion in tightly controlled conditions. This is not to say top-shelf cannabis cannot be grown outdoors, with premium sun-grown flower increasingly popular, but it is incredibly hard to produce commercially at scale.

Cultivating the best cannabis is not only a source of pride and prestige, but when achieved consistently elevates a grower above the competition to the adoration of aficionados. These cannabis connoisseurs spend roughly $320 a month, consume daily and constitute 10% of Canada’s adult population. Although a lucrative demographic for producers, these cognoscente consumers also have the highest standard and are the hardest to please.

CANNABIS

Cultivating top-shelf cannabis relies on nature and nurture in equal parts. Superior genetics are the easiest to secure, but when selecting cultivars growers must keep their environment and experience front of mind. The most sought-after strains are rarely the easiest to grow, with distinguished breeders releasing seeds in limited numbers to protect the cultivar’s exclusivity.

The rareness of these varieties heightens their attractiveness for consumers, but poses a challenge for producers who may not have grown the variety before. What might be desirable for one cultivar may be damaging for another, with growers developing strain-specific knowledge to accentuate certain characteristics. This is often an exercise in trial and error, but can produce extraordinary top-shelf flower with relatively ordinary cultivars.

Growers tend to favour fast flowering plants, to secure more harvests in a year and to maximize revenue. The longer cannabis takes to finish, the greater the window for complications to arise and the and the greater the need for resources, which eats away at an operation’s bottom line. An exception to this rule is the use of auto flowering varieties, which are popular with hobbyists but shunned by commercial producers. This is due to autoflowers being genetically engineered to flower as quickly as possible, at the expense of THC, with the ruderalis subspecies containing very little of the prized cannabinoid.

CULTIVATION

Once genetics have been accounted for, to cultivate top-shelf cannabis producers need to provide the optimal growing conditions. Individual strains favour unique environments, but all require conditions conducive to cannabis cultivation. This includes beneficial lighting, nutrition, temperature and humidity, which is much easier indoors where climate can be closely controlled.

Lighting

A powerful light source is the biggest contributor to flower quality, with photosynthesis critical for growth and trichome production. LEDs have come on leaps and bounds in recent years, as an energy efficient alternative to high pressure sodium vapor (HPS). Many can plug directly into a standard electrical socket, without the need for a weighty external ballast, which heightens their usability.

However, as LEDs fail to provide the light penetration or spectrum of a HPS, growers struggle to produce the same flower density – a key indicator of quality. As LEDs technology progresses, they may eventually usurp the tried and tested HPS, but until then to cultivate top-shelf flower growers should stick with proven grow lights. Top-shelf cannabis needs 50W of light per square foot of canopy, but growers frequently aim to provide 60W or higher, taking care to avoid light burn or detrimental temperatures.

Nutrition

Following lighting, the second biggest environmental factor affecting top-shelf cannabis is the quality and quantity of nutrients. To ensure plants receive the required inputs to reach their potential, commercial cultivators rely on hydro or aeroponics. This keeps a solution containing essential nutrients perpetually within reach, so crops can access sustenance as required.

Proper fertilization is paramount throughout the growth cycles, but is particularly important for root and flower development. When using premixed solutions growers should stick to the provided feed schedule, unless they feel confident enough to customize the regime safely. This requires additional individual dry nutrients, but enables growers to correct deficiencies or overfertilization on the fly.

Living soil and organic growing practices are becoming increasingly popular in the eyes of consumers, with farmers foregoing hydroponics and artificial fertilizers to placate them. Unfortunately, cultivating top-shelf cannabis is incredibly difficult with these restrictions.

CHOPPING AND CURING

To cultivate exceptional flower, growers must dry plants as slowly as possible. Slow drying results in greater resin preservation and a comprehensive purge of chlorophyll, resulting in a smoother and tastier smoke. This requires whole plants to be hanged upside down, in a well-ventilated environment below 20˚C, for up to six weeks.

Once dry, flowers need to be handled carefully to avoid damage, which is why our Gentle Cut buckers have been developed to delicately slice buds from stems, rather than popping them off. Although artisanal harvesting techniques are often associated with top-shelf cannabis, this is no longer the case.

As hand-trimming relies on a motivated and skilled workforce, the appearance of finished product can vary greatly between personnel. On the contrary, specialist elite trimming technologies can be as versatile as a manual trimmer, but capable of infinitely greater efficiency and consistency. With the ability to process wet and dry cannabis to replicate hand-finished flower, the best trimmers can be adjusted by flower density to constantly deliver top-shelf cannabis.